MIL-DTL-917F(SH)

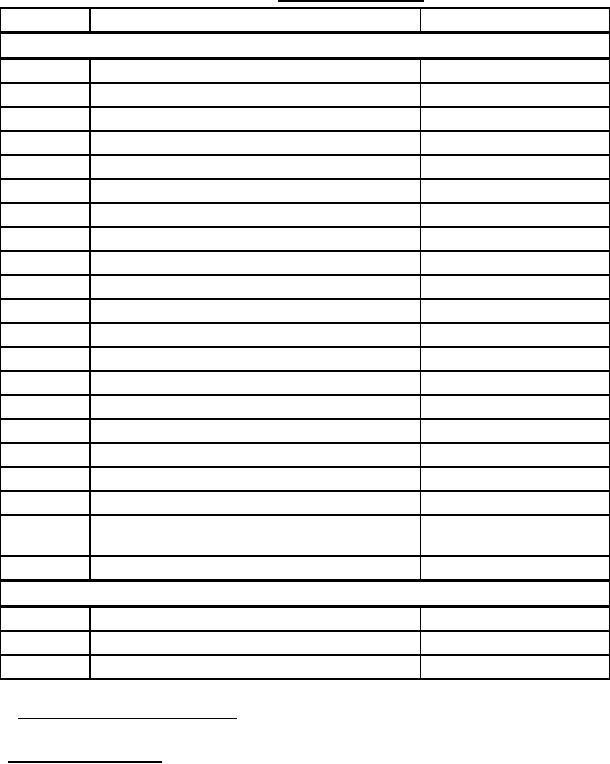

TABLE XXV. Classification of defects.

Categories

Defects

Requirements paragraph

Critical

001

Design

002

Conformance with safety requirements

003

Dynamic balancing

004

Electrical creepage and clearance distances

005

Piping systems

006

Screw threads for fastening devices

007

Parts, materials, and finishes

008

Electrical insulation

009

Dielectric barrier

010

Coils and windings

011

Treating methods

012

Treating materials

013

Varnish treatment

014

Final condition

015

Wire, wiring methods, wire marking, and bus bars

3.12

016

Parts

017

Processes

018

Thermal design

019

Mechanical features

020

Requirements for operating voltages greater than

1,000 V, but less than or equal to 15,000 V

021

IA not as required.

Major

101

Utilization of standard tools

102

Plates for identification and marking information

103

Identification of parts

4.4.1 Dielectric withstanding voltage tests. Dielectric withstanding voltage tests shall be conducted in

accordance with Method 301 of MIL-STD-202 as specified (see 6.2). Test conditions shall be as follows:

a.

Magnitude of test voltage.

(1) For circuits rated 60 V or less, the rms test voltage shall be 900 V.

(2) For circuits rated more than 60 V, the rms test voltage shall be twice rated circuit voltage plus 1,000 V.

(3) For circuits containing parts that are applied within their specified ratings and are in accordance with

part specifications that specify in (1) or (2) herein, the dielectric test voltage for the circuit shall correspond to that

specified for the approved part having the lowest specified dielectric test voltage, but in no case less than:

(a) 900 V for circuits connected to the power supply terminals.

(b) 500 V for circuits electrically isolated from the power supply terminals.

71

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business