MIL-DTL-917F(SH)

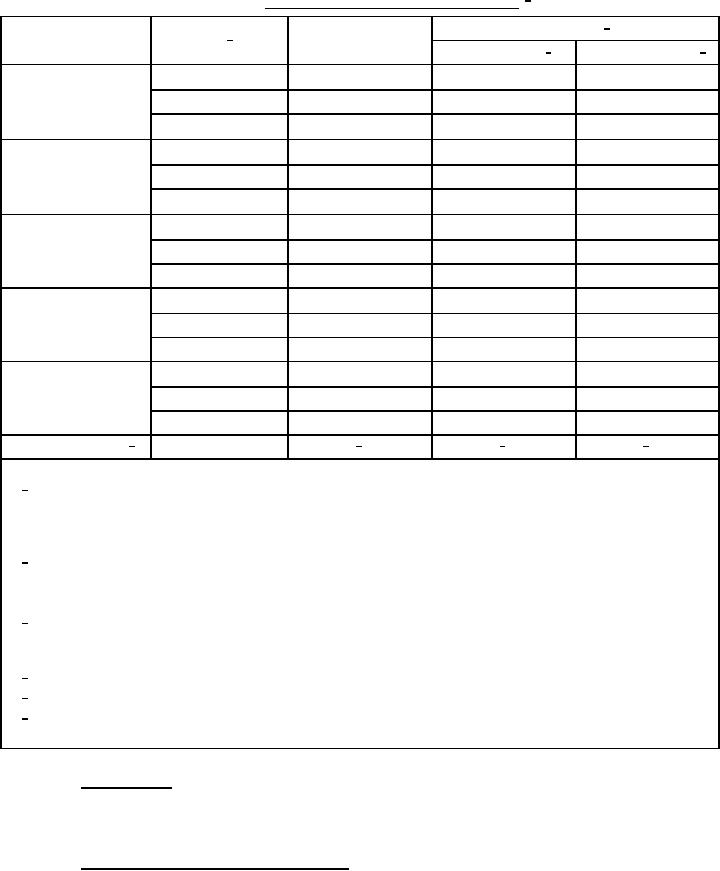

TABLE III. Electrical creepage and clearance distance. 1/

Creepage 3/

2/

Voltage AC or DC

Set

Clearance (inches)

Open (inches) 4/

Enclosed (inches) 5/

/16

/16

/16

1

1

1

A

⅛

⅛

⅛

Up to 64

B

⅛

/8

3

C

½

/16

/16

/16

1

1

1

A

⅛

⅛

Over 64150

B

¼

/8

3

C

¼

¾

/16

/16

/16

1

1

1

A

⅛

⅛

Over 150300

B

¼

C

¼

¾

½

⅛

⅛

/16

1

A

⅛

Over 300600

B

¼

¼

C

¼

¾

½

⅛

/8

3

A

½

Over 6001,000

B

¼

1

¾

C

½

2

1½

Over 1,00015,000 6/

6/

6/

6/

C

NOTES:

1/

Use of electrical parts or assemblies such as potentiometers, connectors, printed wiring assemblies, and

similar devices having lesser creepage and clearance distances is permissible provided these parts and

assemblies conform with applicable military specifications, and their energized portions are enclosed to

protect against entry of dust and moisture.

2/

Set A Normal operating volt-ampere rating up to 50.

Set B Normal operating volt-ampere rating of 50 to 2,000.

Set C Normal operating volt-ampere rating over 2,000.

3/

For top curved surfaces having a radius greater than 3 inches and for top flat surfaces, surface creepage

distance shall be increased 33 percent where these surfaces have irregularities which permit the accumulation

of dust and moisture.

4/

Open: Equipment or parts with open enclosures in accordance with MIL-STD-108.

5/

Enclosed: Equipment or parts with enclosures in accordance with MIL-STD-108, except open enclosures.

6/

For voltages above 1,000 V, but less than or equal to 15,000 V, use electrical creepage and clearance values

in accordance with IACS (UR) E11.

3.2.23 Piping systems. Piping systems shall have socket welded, butt welded, or flanged fittings. Silver

brazing and threaded pipe fittings shall not be used. For additional guidance, see S9086-RK-STM-010/505.

Requirements for material identification and control of piping systems shall be in accordance with

0948-LP-045-7010.

3.2.24 Screw thread standards for fastening devices. Screw threads for all threaded fastening devices shall be

in accordance with ASME B1.1. The threads shall be the coarse-thread series, unified form, Class 2A/2B unless the

component design indicates a necessity for the use of the fine thread series.

23

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business