MIL-DTL-917F(SH)

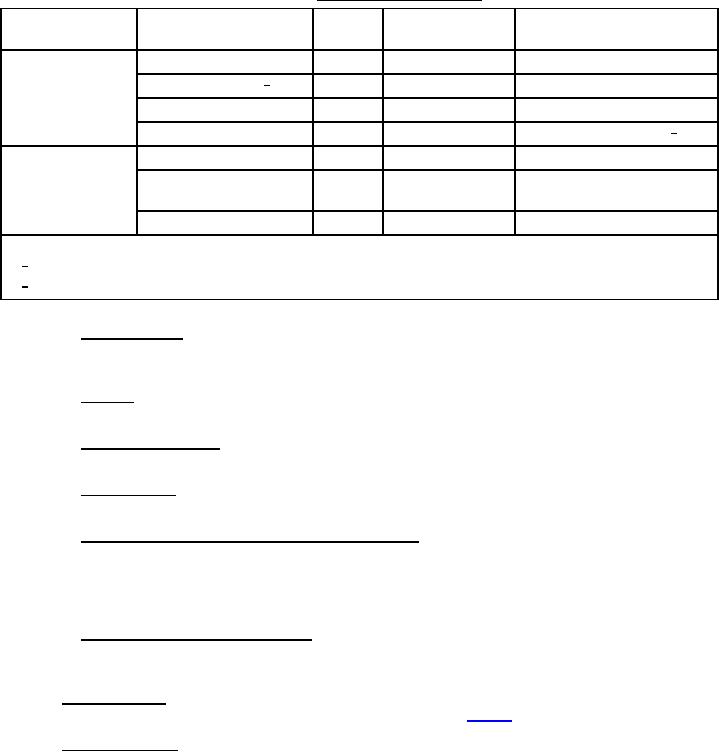

TABLE XII. Slot-wedges (non-metallic).

Applicable

Item

Material

Type

Max. temperature, °F (°C)

document

Slot wedge, flat

Glass melamine

GME

MIL-I-24768/1

311 (155)

Glass silicone 1/

GSG

MIL-I-24768/17

392 (200)

Glass epoxy

GEE

MIL-I-24768/3

266 (130)

266-356 (130-180) 2/

Glass polyester

GPO-N1

MIL-I-24768/4

Slot wedge, formed

Polyester film

G

MIL-I-631

248 (120)

Polyester mat-film

----

MIL-I-22834 (for

266 (130)

guidance only)

Polyamide paper

----

ANSI/NEMA FI 3

392 (200)

NOTES:

1/

See 3.3.1.4 for restrictions on the use of silicones.

2/

Limiting temperature will depend on type of resin used.

3.4.13 Insulating panels. Insulating panels shall be in accordance with Type GME of MIL-I-24768/1, Type

GSG of MIL-I-24768/17, or MIL-I-24768, and Type GPO-N2 or GPO-N3 of MIL-I-24768/5 or MIL-I-24768/6,

respectively.

3.4.14 Sleeving. Sleeving shall be in accordance with MIL-I-3190, MIL-I-631, or MIL-I-22129. Heat

shrinkable sleeving shall be in accordance with SAE-AMS-DTL-23053.

3.4.15 Commutator insulation. Commutator segments shall be inorganic bonded mica or reconstructed mica

with polyester or melamine binders.

3.4.16 Band insulation. Insulation under banding wire shall be mica-glass composite in accordance with

MIL-I-3505, or laminated plastic material with varnished glass cloth underlayment.

3.4.17 Lacing and tying cords for varnished coils and windings. Lacing and tying cords shall be cotton cable

laid armature twine for Class 105 insulation; Form 2, Class C in accordance with MIL-Y-1140 for Classes 130 and

155 insulation; and silicone treated glass cord for Classes 180 and 200 insulation. Silicone or

polytetrafluoroethylene treated flat glass sleeving may be used for Classes 180 and 200 only (see 3.3.1.4 for

restrictions on use of silicone).

3.4.18 Armature and coil banding using glass. Semi-cured thermosetting resin treated glass insulation tape

may be used for armature and coil banding in lieu of steel wire banding. The glass banding materials and methods

of application shall be in accordance with MIL-I-24178.

3.5 Dielectric barrier. The insulation used for the major ground insulation wall on electric equipment shall

provide suitable dielectric barrier action. Satisfactory materials are listed in table X.

3.6 Coils and windings. Coils and windings shall be designed for maximum protection from environmental

hazards, and replacement parts containing coils shall not be adversely affected by normal handling during

replacement in cramped locations.

Slotcells shall be folded under the slot wedge if a flat wedge is used or slotcells shall be inserted inside the slot

wedge if a formed (curved) wedge is used. The wedge shall extend the full length of the slotcell, and shall be

positioned so as to cover the slotcell completely.

37

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business