MIL-DTL-917F(SH)

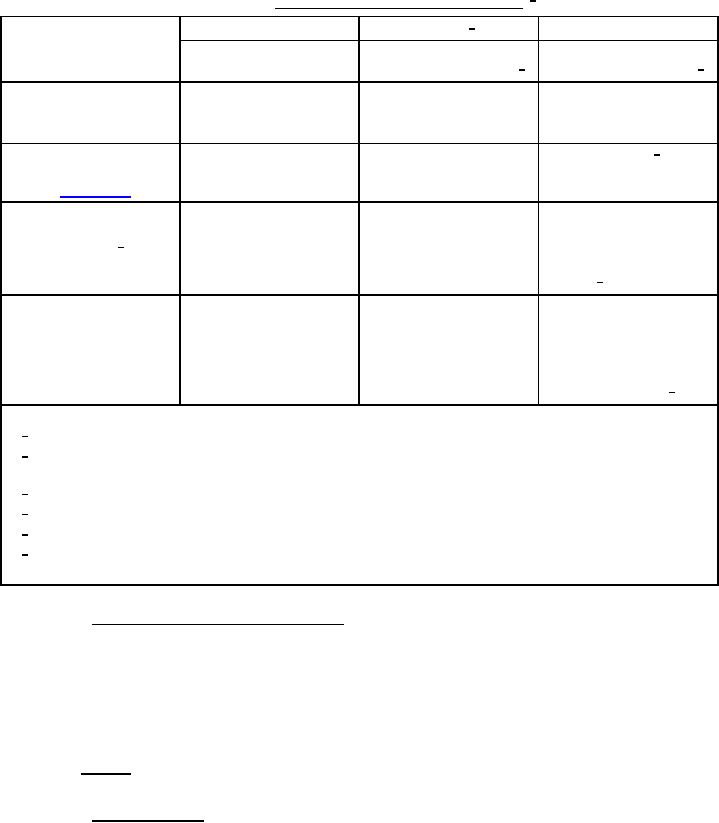

TABLE XXII. Painting of metal for corrosion resistance. 1/

Primer 2/

Topcoats

Pretreatment

Metal

Specification minimum

Specification minimum

Specification

thickness (millimeters) 3/

thickness (millimeters) 3/

0.025

Ferrous metal

TT-C-490, Type I, II;

TT-P-645 or

MIL-DTL-53084

MIL-DTL-15090 4/, 2

Ferrous metals with

TT-C-490, Type III;

0.05; Formula 150

coats Type II or each

treatments other than those

MIL-DTL-24441

0.025 Type III

listed in table XVIII

Ferrous metals and

TT-P-645

0.025

Class 2 second coat may

aluminum alloys both used

be omitted on inside of

in same assembly 5/

enclosure and equipment

to be installed in interior

of ships 6/

For MIL-DTL-5541

Aluminum and aluminum

MIL-DTL-53084;

0.025

pretreated materials, only

alloys

TT-C-490, Type I;

a single coat should be

MIL-DTL-5541, Type II,

added to equipment

Class 1A

installed interior or

exterior of the ships 6/

NOTES:

1/

For details on painting procedures, see 3.14.2.

2/

The preferred primer is MIL-DTL-53084. TT-P-645 is second preference. If MIL-PRF-24712 is chosen as a

topcoat, no primer is required.

3/

Minimum dry film thickness.

4/

Applies to ferrous metals.

5/

For metals in direct contact, see 3.4.2.1.

6/

MIL-PRF-24712 is the preferred topcoat applied in one coat at 0.0049 to 0.0098 in. (0.125 to 0.250 mm).

MIL-DTL-15090, Types I, II, or III, Class 1 is second preference.

3.14.1.1 Interior surfaces of motors and generators. In case of salient pole motors and generators, metal

surfaces of armatures, rotors, and other rotating members shall be coated with insulating varnish. Non-rotating

interior surfaces of motors and generators may either be coated with insulating varnish or treated and painted as

required for other parts (see 3.14.1). When insulating varnish is used, no other treatment or processing is required.

Insulating varnish may be applied during the normal varnishing process required for windings or applied as a

separate process. Unless otherwise specified in the individual equipment specification or the contract or order, a

minimum of two coats shall be applied, using any method which will ensure coverage of all surfaces. Insulating

varnish shall be in accordance with MIL-I-24092.

3.14.2 Painting. The preferred painting method for prevention of corrosion and for environmental reasons is

powder coating. Powder coatings used shall be approved in accordance with MIL-PRF-24712.

3.14.2.1 Parts to be painted. Where necessary to obtain corrosion resistance, metal parts, except those of

3.14.2.2, shall be painted. Surfaces of corrosion-resistant metal (see 3.3.2.3) may be painted for appearance. When

a gray painted exterior is specified (see 6.2), exterior parts, except those cited in 3.14.2.2, shall be painted whether

or not corrosion-resistant.

60

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business