MIL-DTL-917F(SH)

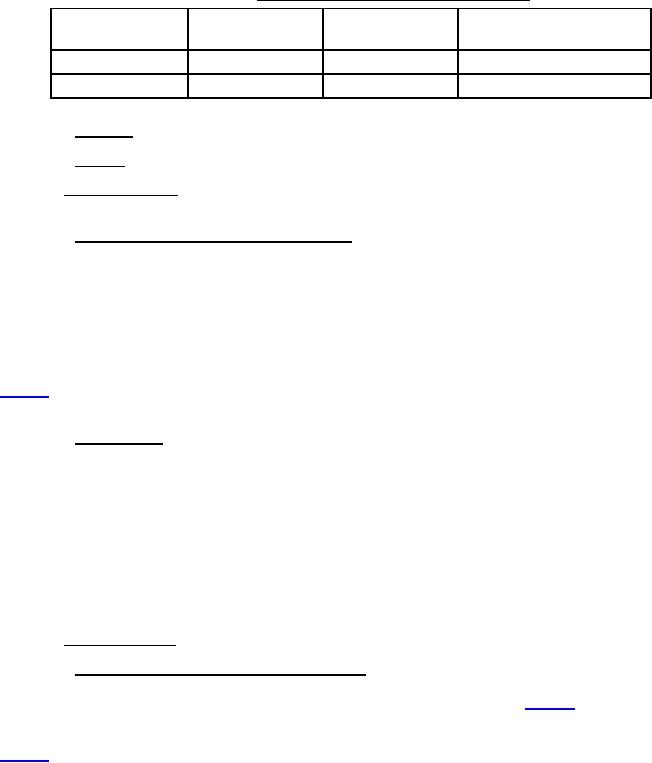

TABLE VIII. Molding compounds (thermoplastic material).

Applicable

Compounds

Type

Max. temperature, °F (°C)

document

Polyamide (nylon)

Type III, Grade E

ASTM D6779

221 (105)

Polycarbonate

----

ASTM D3935

221 (105)

3.4.1.4 Ceramics. Ceramics may be used only where they constitute integral portions of specified parts.

3.4.1.5 Silicone. The use of silicone shall be as specified in 3.3.1.4.

3.4.2 Insulating material. Detailed discussion of electrical insulation and temperature limits is contained in

IEEE 1.

3.4.2.1 Classes and definitions of insulating materials. Temperature classes of insulating materials have

traditionally been established by definition based on a chemical composition of the materials. Methods of

temperature classification based on the results of thermal evaluation tests are coming into use as specified (see 6.2).

Since the temperature classification of a material that has been accepted for a long time will have been established

by field experience, its life-temperature characteristics determined by test provide a basis for comparison with the

thermal life of a new material. The purpose of assigning each material to a definite temperature class, therefore, is

to facilitate comparisons between materials and to provide a single number to designate each class for purposes of

standardization. The life expectancy under the test conditions may be shorter than, and has no direct relation to, the

life expectancy of the material in actual service. Materials or combinations of materials other than those listed in

table IX may be included in a given class if, by experience or accepted tests, they can be shown to have comparable

thermal life at the associated temperature index.

3.4.2.2 Accepted tests. The words "accepted tests" in paragraph 3.4.2.1 above are intended to refer to

recognized industry or military test procedures established for the thermal evaluation of materials by themselves or

in simple combinations. Experience or test data used in classifying insulating materials are distinct from the

experience or test data derived for the use of materials in complete insulation systems. The thermal endurance of

complete systems may be determined by test procedures specified elsewhere in this specification or in related

equipment specifications. A material that is classified as suitable for a given temperature may be found suitable for

a different temperature, either higher or lower, by insulation system test procedures. For example, it has been found

that some materials suitable for operation at one temperature in air may be suitable for a higher temperature when

used in a system operated in an inert gas atmosphere. It is important to recognize that other characteristics, in

addition to thermal endurance, such as mechanical strength, moisture resistance, and corona endurance, are required

in varying degrees in different applications for the successful use of insulating materials.

3.4.3 Insulation systems.

3.4.3.1 Temperature classification of insulation systems. Materials of a given temperature index may be used

as parts of complete insulation systems that are assigned widely different temperatures, depending on the results of

thermal tests of the insulation system. The insulation system classification specified in table IX shall be used for

Navy equipment and shall be specified in the individual equipment specification (see 6.2). The materials used in

electrical systems shall be characterized by the specific limiting temperatures at the temperature indices shown in

table IX. These temperatures are based on service experience or on accelerated life test data that demonstrates an

equivalent life expectancy. New or modified systems shall be evaluated by acceptance test procedures and, when so

evaluated, shall have equal or longer thermal endurance than a service-proven system of the class at the test

conditions. A new insulation system may also be classified in a higher class by test if it has equal or greater thermal

endurance at higher test temperatures when compared to a service proven insulation system under the same test

conditions.

33

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business