MIL-DTL-917F(SH)

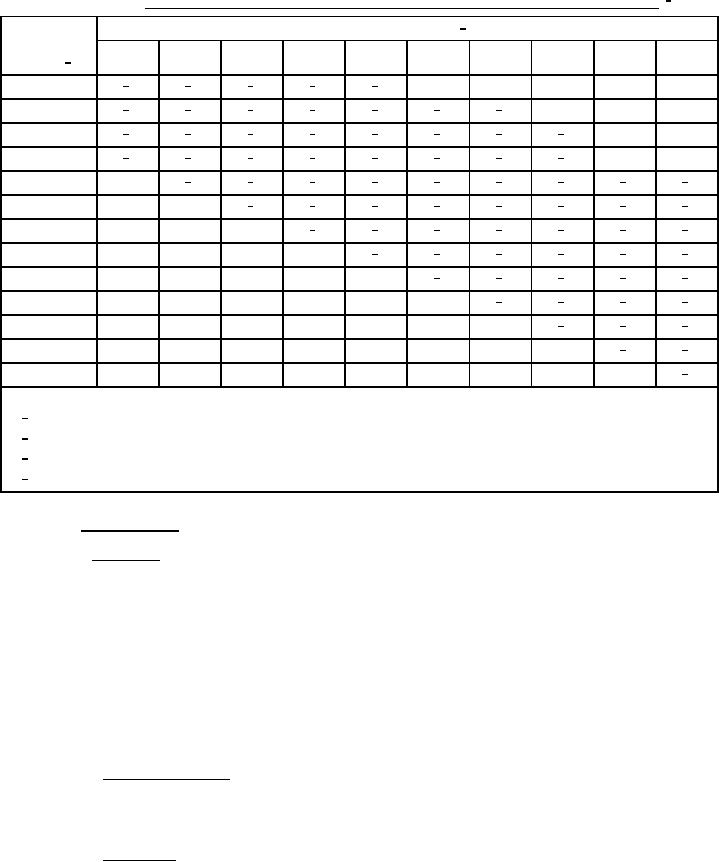

TABLE XVIII. Square and rectangular insulated magnet wire sizes available to naval repair activities. 1/

Bare width (mils) 2/

Bare

thickness

63

80

100

125

160

200

250

315

400

500

(mils) 2/

3/

3/

3/

4/

4/

32

3/

3/

4/

4/

4/

4/

4/

40

3/

4/

4/

4/

4/

4/

4/

4/

50

4/

4/

4/

4/

4/

4/

4/

4/

63

4/

4/

4/

4/

4/

4/

4/

4/

4/

80

4/

4/

4/

4/

4/

4/

4/

4/

100

4/

4/

4/

4/

4/

4/

4/

125

4/

4/

4/

4/

4/

4/

160

4/

4/

4/

4/

4/

200

4/

4/

4/

4/

250

4/

4/

4/

315

4/

4/

400

4/

500

NOTES:

1/

Types suitable for any application up through 428 °F (220 °C).

2/

Dimensions listed are nominal values; tolerances of ANSI/NEMA MW 1000 shall apply.

3/

Available in Types M2 and M4.

4/

Available in Types M2, M4, and M2DgGM.

3.12.2 Wiring methods.

3.12.2.1 Harnessing. Wiring shall be neatly formed into groups which are locked, sleeved, tied, or clamped in

a manner that provides support and prevents chafing of the wire insulation due to vibration and shock. There shall

be no splices in the wire and all connections shall be made at the terminals of the devices, at terminal blocks, or at

part mounting boards. Wire groups running from hinged panels and doors shall be flexible and as specified in

3.12.2.1.3. Finished harness diameter shall not restrict flexibility requirements where necessary. The use of

preformed cables and wiring harnesses is preferred to the point-to-point method of wiring. Conductors combined

into a harness shall be securely held together by means of lacing, ties, or clamps, or be permanently mounted in

cabling ducts. Individual conductors which are thus combined shall lie essentially parallel to one another and shall

not entwine other conductors. This requirement does not preclude the use of twisted pairs or triads where required

for electrical reasons. The combined heating of bundled wires or proximity heating by components shall not cause

maximum temperatures of harnessed wire insulation to be exceeded. The National Electric Code NFPA 70 shall be

used for calculations and adjustments of wire ampacity when multiple conductors are employed.

3.12.2.1.1 Harnessing materials. Cord, tape, or sleeves for wire bundle harnessing, tying, lacing, or sleeving

shall be of non-flammable materials. Metal ties or clamps, if used, shall be covered with non-flammable insulating

material, and plastic straps, clamps, and mounting hardware shall be in accordance with SAE-AS23190. Refer to

MS21919 for additional guidance.

3.12.2.1.2 Lacing cord. Lacing cord shall be Type P unwaxed nylon in accordance with MIL-DTL-713 or

Type SR-4.5 glass fiber (resin-filled) cord in accordance with MIL-I-3158 for temperatures up to 221 °F (105 °C),

neoprene treated glass cord in accordance with MIL-Y-1140 for temperatures up to 266 °F (130 °C), and silicone

treated glass cord or sleeving for temperatures up to 392 °F (200 °C) (see 3.4.17). Polyamide tape, in accordance

with Type IV or V of A-A-52080, A-A-52081, A-A-52082, A-A-52083, and A-A-52084, also may be used for

temperatures up to 392 °F (200 °C).

43

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business