MIL-DTL-2212K(SH)

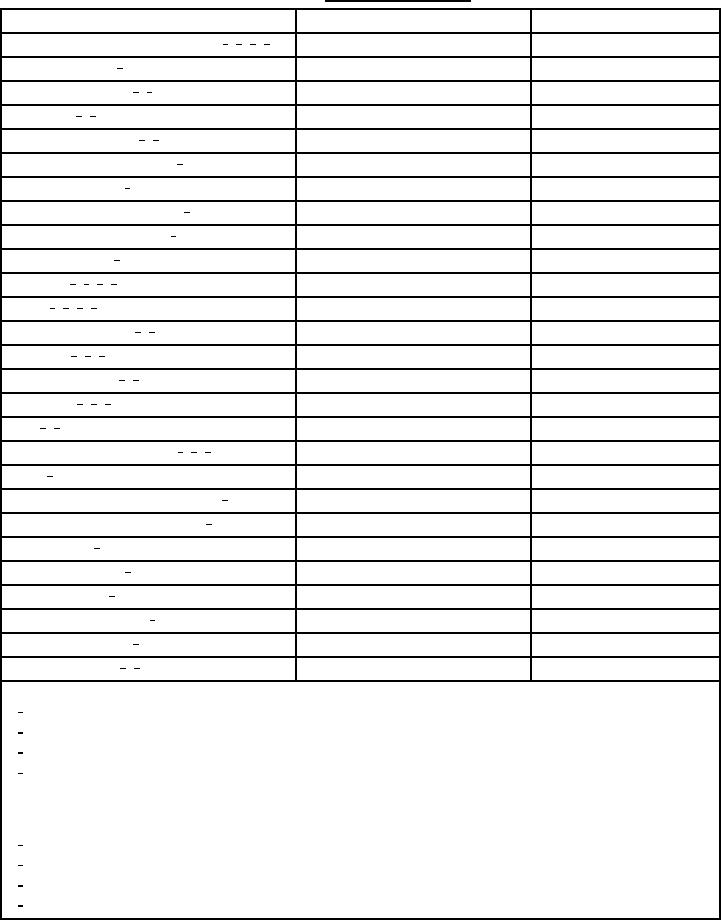

TABLE XI. Qualification inspection.

Inspection

Requirement

Test method

Examination and general operation 1/, 2/, 3/, 4/

Voltage variation 4/

Overload protection 1/, 2/

Endurance 1/, 2/

Mechanical interlock 1/, 4/

Relay setpoint repeatability 5/

Relay recycle time 5/

Switch setpoint repeatability 3/

Effectiveness of enclosure 6/

Temperature rise 1/

Vibration 1/, 2/, 3/, 4/

Shock 1/, 2/, 3/, 4/

Insulation resistance 1/, 2/

Dielectric 1/, 2/, 4/

Terminal strength 1/, 2/

Inclination 1/, 2/, 3/

EMI 2/, 7/

Pickup and dropout voltage 1/, 2/, 4/

Noise 7/

Steady-state voltage and frequency 2/

Transient voltage and frequency 2/

Spike voltage 2/

Power interruption 2/

Leakage current 2/

Output leakage current 2/

Output voltage drop 2/

Voltage ramp rate 7/, 8/

NOTES:

1/

Test applies for qualification of individual contactors and associated switching devices.

2/

Test applies for qualification of solid-state associated switching devices.

3/

Test applies for qualification of pressure and temperature switches.

4/

Test applies for qualification of controllers which are assembled with components qualified to this specification.

Completely assembled nonreversing, dripproof motor controller of each size for only the following basic types:

Across-the-line (single-speed and two-speed); reduced voltage (autotransformer, primary resistor, primary

reactor, wye-delta, and resistor).

5/

Test applies only to qualification of time delay relay.

6/

Test applies to any device with an enclosure.

7/

When required (see 6.2).

8/

Test applies to qualification of devices operated under the condition of voltage ramp.

30

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business