MIL-DTL-2212K(SH)

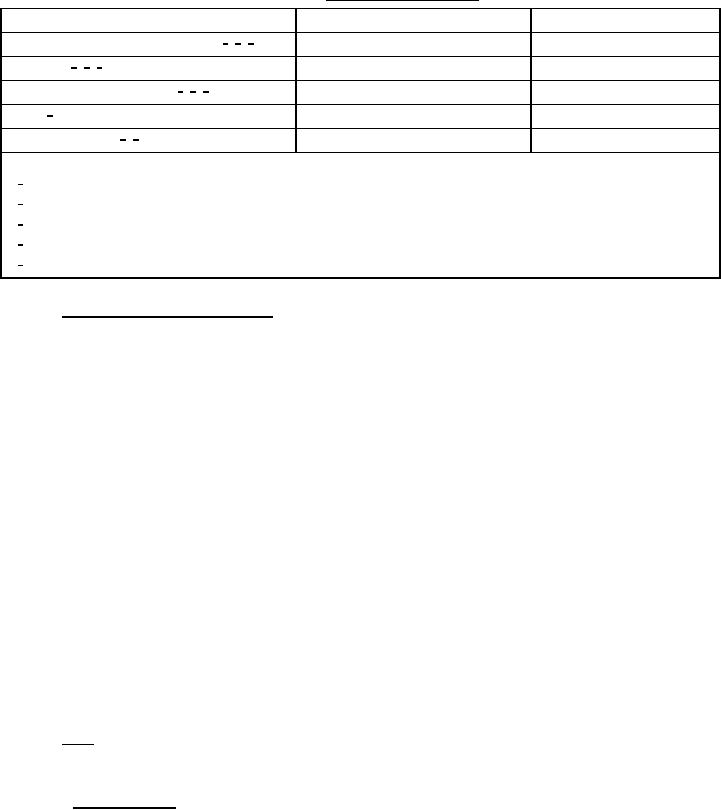

TABLE XIII. Conformance inspections.

Inspection

Requirement

Test method

Examination and general operation 1/, 2/, 4/

Dielectric 1/, 2/, 4/

Pickup and dropout voltage 1/, 2/, 4/

Noise 3/

Voltage ramp rate 3/, 5/

NOTES:

1/

Test applies for individual contactors and associated switching devices.

2/

Test applies for solid-state associated switching devices.

3/

When required (see 6.2).

4/

Test applies for all motor controllers.

5/

Test applies to qualification of devices operated under the condition of voltage ramp.

4.5 Examination and general operation. Equipment shall be examined to determine that the material, safety to

operating personnel, and construction are in accordance with the requirements of this specification without

disassembling the unit in such a manner that its performance, durability, or appearance would be affected. The

general operation shall include energizing and operating the equipment to ascertain that the required operating

features of the unit function properly. In particular, it shall be determined that the required sequence of operation

has been attained and that the protective devices, as applicable, operate as required. External devices shall be

simulated as necessary to perform operational tests. Specific electrical loads are not required but at least one set of

each type of contact on every device shall be monitored by suitable means (voltage recorder, ohmmeter, indicator

light, and so forth) to check the opening and closing performance. For qualification and conformance testing of

solid-state devices that are programmable and have networking-interfacing capabilities, the following additional

requirements are included:

a. Test and demonstrate all executable commands and status requests for all installed network interface

b. Test and demonstrate the operation of all inputs and outputs via both local and network protocol commands

as appropriate for all configurations the device is capable of being configured (i.e., single-speed, multi-speed,

reversing, etc.).

c. Test and demonstrate all configuration types to which the device is capable of being configured (i.e.,

single-speed, multi-speed, reversing, etc.).

d. Test and demonstrate proper operation of the LVP and LVR modes for all available configurations

(see 3.16.5.1).

e.

Demonstrate ability to display firmware version locally or via network interface if applicable.

f.

Demonstrate password protection configuration feature, if installed (see 3.16.5.1a).

4.6 Tests. All tests will be conducted at an ambient temperature range between 50 °F and 104 °F (10 °C and

40 °C), except for the temperature rise test and pickup and dropout voltage tests, for qualification and conformance

inspections.

4.6.1 Temperature rise. Temperature rise tests shall be performed for conformance inspection on the first

production run only. Temperature rise tests are not required on subsequent production runs unless a change is made

in design. The test methods used and the precautions observed in conducting temperature rise tests shall be in

accordance with NEMA ICS 1 and the following:

a. Temperature rise tests shall be made under conditions equivalent to normal operating conditions at rated

voltage, frequency, and load, with the duty specified to determine that the rises specified in 3.17.1 are not exceeded.

b.

Tests shall be made with equipment in its enclosure if enclosure is provided as part of the equipment.

32

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business