MIL-DTL-917F(SH)

Procedure 2:

a.

Prior to storage out-of-doors:

(1) Apply corrosion protection in accordance with Grade 1 of MIL-PRF-16173.

b.

After storage out-of-doors:

(1) Remove corrosion protection with solvent.

(2) Complete fabricating operations and follow normal painting procedures as specified in 3.14.2.3.

3.14.3 Soldering. Only non-corrosive fluxes shall be used unless it can be shown that all corrosive products

have been satisfactorily removed or neutralized after soldering. Soldering materials and processes shall be in

accordance with J-STD-001. Soldered connections shall be of such character and quality that the bending between

the soldered items may be determined by visual examination. Excessive amounts of solder shall not be used.

Soldering alone shall not be depended upon for a satisfactory connection. Where wire and terminals are joined to be

soldered, the wire shall be hooked, wrapped around, or otherwise secured to the terminals, prior to soldering. Solder

for connection of electrical windings and parts shall be as specified in 3.14.3.1 and 3.14.3.2, respectively.

3.14.3.1 Solder for windings. Solder for connection of electrical windings shall be in accordance with one of

the compositions shown in table XXIII.

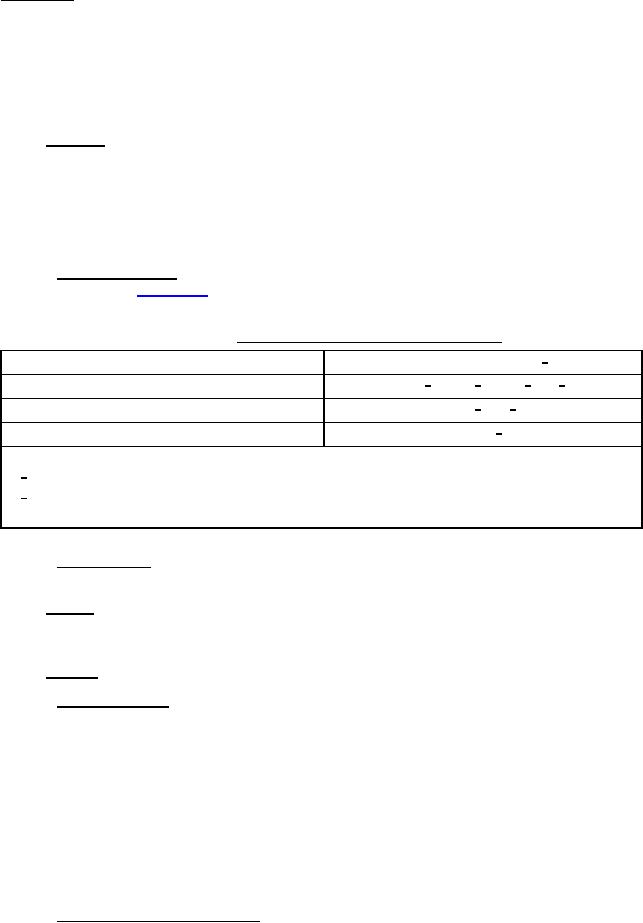

TABLE XXIII. Solder for connection of electrical windings.

Solder composition 1/

Windings

Sb5 1/, Sn60 1/, Sn63 1/, tin 2/

Class 105 or 130 insulation, stationary

Sb5 1/, tin 2/

Class 105 or 130 insulation, rotating

Sn10 1/

Class 155, 180, and 200

NOTES:

1/

Composition in accordance with J-STD-004, J-STD-005, and J-STD-006.

2/

Commercially pure tin. Use of tin solder shall be limited to equipment known to be intended for

installation in interior of ship.

3.14.3.2 Solder for parts. Solder for connections of electrical and electronic parts shall be composition Sn60 or

Sn63 of J-STD-004, J-STD-005, and J-STD-006.

3.14.4 Brazing. Brazing alloys for electrical connections shall be in accordance with S9086-CH-STM-010/074

or QQ-B-654. Brazed electrical connections shall not be used where disconnection and reconnection for

maintenance purposes is required.

3.14.5 Welding.

3.14.5.1 Structural welding. Structural welding and applied processes shall be in accordance with

S9074-AR-GIB-010/278 with the following exception. Welding practices in accordance with applicable American

Welding Society (AWS) specifications may be used for welding applications not referenced in

S9074-AR-GIB-010/278. Structural welding and allied processes of S9074-AR-GIB-010/278 will be supplemented

as follows:

a.

Spray metalizing of shafts will not be permitted.

b.

Efficiency of welded joints for motors and generators shall be as follows:

(1) Rotating parts 100 percent.

(2) Stationary parts subject to stress 80 to 100 percent.

(3) Stationary parts not subject to stress as required to meet applicable impact shock requirements.

3.14.5.2 Welding of electrical connections. Welds and welding processes for electrical connections shall be in

accordance with MIS-PRF-53095.

62

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business