MIL-DTL-917F(SH)

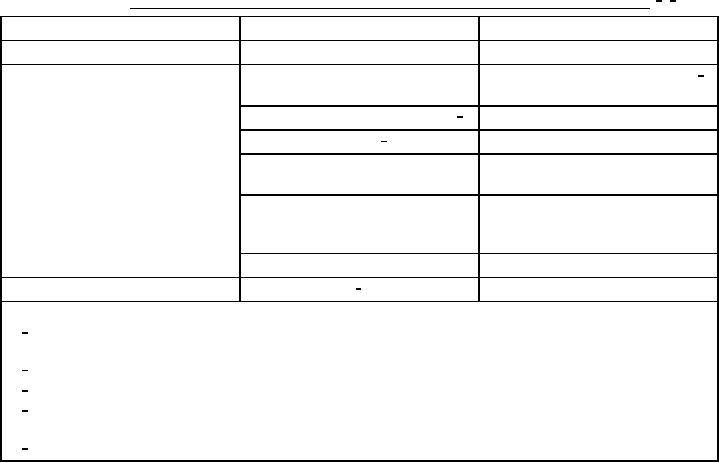

TABLE XXI. Processing of metals for corrosion resistance treatments where painting is not required. 1/, 2/

Metal

Treatment

Treatment document

Corrosion-resistant (see 3.3.2.3)

Not required

----

MIL-DTL-83488, Class 3, Type II 3/

Aluminum coating, ion vapor

deposited

Zinc coating (hot-dip galvanizing) 4/

ASTM A153/A153M

Electrodeposited zinc 4/

ASTM B633

Electrodeposited nickel

SAE-AMS-QQ-N-290, Type I (DS),

Ferrous metals

or ASTM B456

Nickel undercoat plus

SAE-AMS-QQ-N-290, Type I (DS),

electrodeposited chromium

or ASTM B456, Type DS, and

SAE-AMS2460

Electrodeposited silver

ASTM B700

Anodic treatment 5/

Aluminum and aluminum alloys

MIL-A-8625

NOTES:

1/

Corrosion-resistant metal or metals processed for corrosion resistance may be painted for appearance and as

specified in 3.14.2.1.

2/

Tin plating on copper conductors is at the option of the manufacturer.

3/

These coatings have superior corrosion resistance in marine atmosphere and are preferred.

4/

Unpainted zinc coatings shall not be used on equipment or parts to be packed in unventilated containers made

of unseasoned wood, unless desiccant is enclosed.

5/

Anodized treatment is considered electronically non-conductive.

59

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business