MIL-DTL-917F(SH)

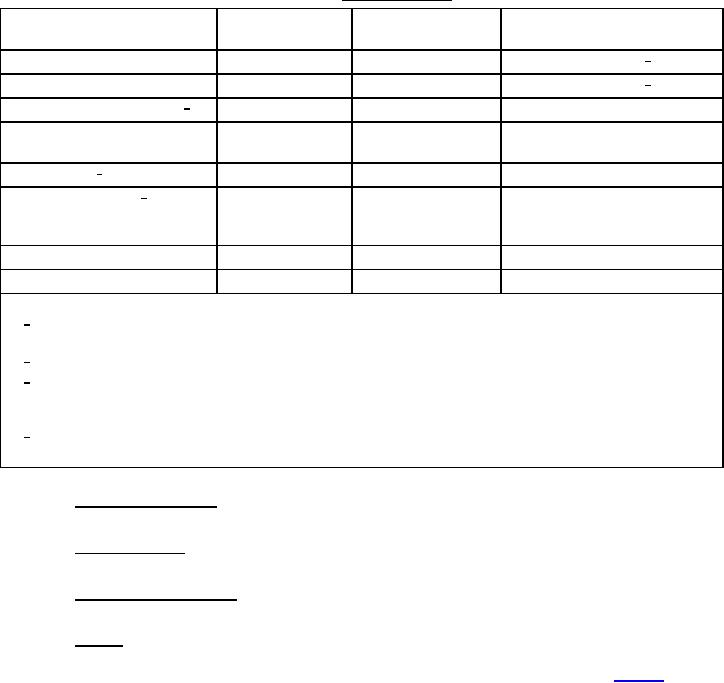

TABLE X. Ground insulation.

Applicable

Material

Type, class, or grade

Max. temperature, °F (°C)

document

As required 1/

Reinforced mica splittings

MIL-I-3505

All types

As required 1/

Mica-paper composites

ANSI/NEMA FI 1

All types

Mica-paper (silicone binder) 2/

ANSI/NEMA FI 1

All types

392 (200)

Polyester mat-polyester-film

MIL-I-22834 (for

All types

266 (130)

guidance only)

Polyester film 3/

MIL-I-631

Type G

248 (120)

Varnished glass cloth 4/

ASTM D2400 (for

Grade O

194 (90)

guidance only) and

ASTM D2754

Polymeric resin film

ASTM D5213

Type I, Class E

302 (150)

Polyamide paper

ANSI/NEMA FI 3

All types

428 (220)

NOTES:

1/

The temperature class is determined by the binder used; suitable binders are available for 311 °F (155 °C),

356 °F (180 °C), and 392 °F (200 °C) use.

2/

See 3.3.1.4 for equipment restrictions on the use of silicones.

3/

Polyester film is restricted to static parts of electrical equipment and to rotating equipment of outside frame

diameter less than 10 inches. The minimum film thickness shall be 0.0075 inch for rotating equipment and

0.001 inch for static equipment.

4/

Varnished glass cloth for ground insulation applications shall be limited to control circuits up to

50 volt-amperes (VA).

3.4.6 Core tubes and bobbins. Core tubes and bobbins for mechanical support shall be laminated plastic types

3.4.7 Toroid core boxes. Core boxes for toroid windings may be aluminum with overwrappings of either

pressure sensitive insulating tape (see 3.4.11) using the fluidized bed or spray process and oven cured.

3.4.8 Layer and phase insulation. Glass thread interweaving may be used on layer wound magnet coils. Other

types of layer or phase insulation shall be any of the types specified in 3.4.5 except varnished glass cloth.

3.4.9 Spacers. Spacer insulation such as slot spacers, coil separators, duct spacers, end plate insulation,

supporting rings, interpole washers, or any other flat or formed pieces used primarily for mechanical separation as

part of a coil or winding shall be rated at a minimum of 311 °F (155 °C) and selected as specified in table XI.

35

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business