MIL-DTL-917F(SH)

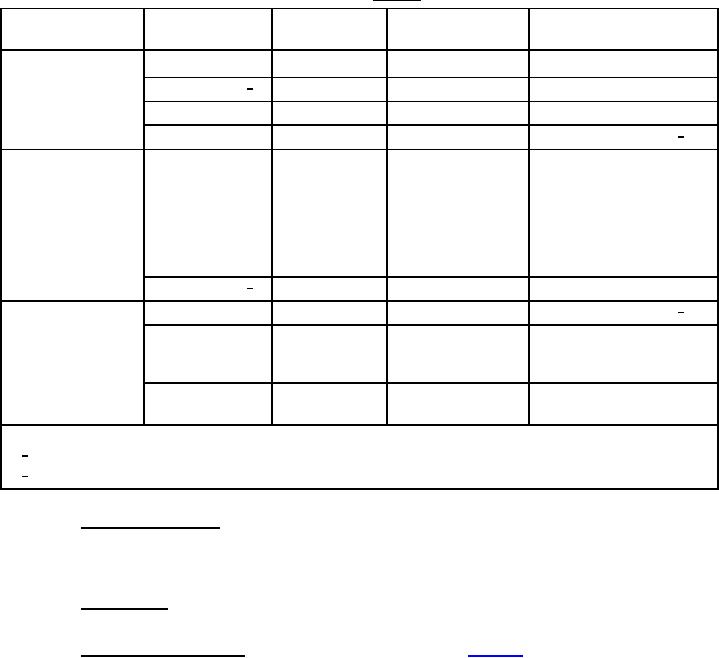

TABLE XI. Spacers.

Applicable

Item

Material

Type or grade

Max. temperature, °F (°C)

document

Spacer (rigid-flat)

Glass melamine

GME

MIL-I-24768/1

266 (130)

Glass silicone 1/

GSG

MIL-I-24768/17

392 (200)

Glass epoxy

GEE

MIL-I-24768/3

266 (130)

266-356 (130-180) 2/

Glass polyester

GPO-N1

MIL-I-24768/4

Spacer (rigid-tube-

Glass melamine

GMG, TR

MIL-I-24768/8,

266 (130)

rod, or formed

MIL-I-24768/10,

shape)

MIL-I-24768/11,

MIL-I-24768/12,

MIL-I-24768/13,

MIL-I-24768/14,

and MIL-I-24768/16

Glass silicone 1/

GSG

MIL-I-24768/17

356 (180)

266-392 (130-200) 1/

Spacer (flexible)

Reinforced mica

All

MIL-I-3505

Varnished glass

0

ASTM D2400 (for

194 (90)

guidance only) and

ASTM D2754

Polymeric resin

Type I, Class E

ASTM D5213

302 (150)

film

NOTES:

1/

See 3.3.1.4 for restrictions on the use of silicones.

2/

Limiting temperature will depend on the type of resin or binder used.

3.4.10 Binding tape and strips. Binding tape and strips (porous for later impregnation or filling) for mechanical

purposes shall be glass in accordance with MIL-Y-1140. For Class 130 and higher temperature applications, glass

tape and cloth shall be heat cleaned to remove sizing. Subsequent chemical treatment may be used if compatible

with varnish used for filling or impregnating (see 3.4.17).

3.4.11 Electrical tape. Electrical tape shall be in accordance with MIL-I-631. Electrical pressure-sensitive tape

shall be in accordance with MIL-I-24391, MIL-I-19166, or Types AFT, GFT, EG, or MFT of A-A-59770.

3.4.12 Slot-wedges (non-metallic). Slot-wedges shall be selected from table XII.

36

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business