MIL-DTL-16036M(SH)

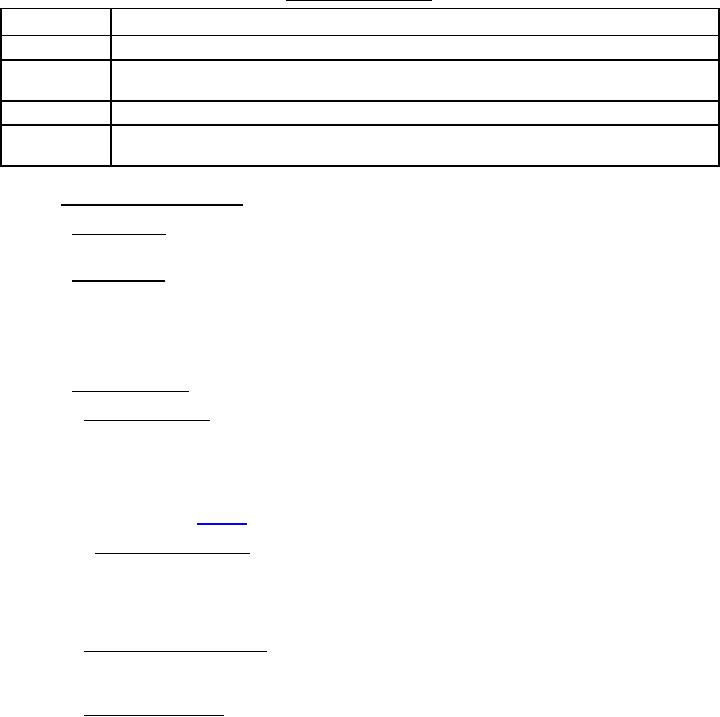

TABLE XI. Classification of defects Continued.

Classification

Defects

Minor:

202

Identification and information plates not of specified shape, size, thickness, location, letter, and

fastening.

203

Special tools, if required, not furnished.

204

Switchboard not cleaned following construction; loose parts, dirt, or metal shavings not removed

from unit.

4.4 Examination and test methods.

4.4.1 Test equipment. Test equipment shall be as specified in MIL-E-917, except that the shock machine shall

be in accordance with MIL-S-901.

4.4.2 Test conditions. Unless otherwise required in the detailed test herein, the inspection and tests of 4.4 shall

be performed under the following conditions. Ambient conditions within the specified ranges need not be

controlled:

a.

Temperature from 50 to 122 °F (10 to 50 °C).

b.

Attitude: Normal operation position.

4.4.3 Detailed inspection.

4.4.3.1 General examination. The completed unit shall be given a thorough examination to determine that it

conforms to the applicable specifications and drawings with respect to safety, material, finish, workmanship,

construction, assembly, electrical parameters and function of electrical components, dimensions, weight, and

marking of identification and description plates. This examination shall be limited to those that can be performed

without disassembling the unit in such a manner that its performance, durability, or appearance would be affected.

This examination shall include a check of operating controls, circuit functions, and adjustments as applicable.

Defects shall be as specified in table XI.

4.4.3.1.1 The 100-hour burn-in test. The 100-hour burn-in test shall be conducted by energizing control voltage

to the equipment for 100 hours at nominal voltage and frequency, ambient temperature and with all control voltage

inputs and outputs connected to effect maximum rated loading. If a failure occurs during this test, the failure shall

be corrected and test shall be repeated from the start. The 100-hour burn-in test may be accomplished at the end of

first article testing.

4.4.3.2 Maintainability demonstration. When specified (see 6.2), compliance with 3.23 shall be verified

through a maintenance demonstration procedure, maintenance task selection, and maintenance task performance in

accordance with Test Method 1 of Appendix B of MIL-HDBK-470.

4.4.3.3 High-impact shock test. Switchboard sections (see 6.3.9) shall be subjected to Type A, Class I,

high-impact shock test in accordance with MIL-S-901. Passing subsidiary component testing, such as QPL testing,

does not preclude the requirement of system level shock qualification. The complete switchboard section, including

all subsidiary components and subassemblies installed within the switchboard during the test, shall meet the shock

test acceptance criteria. The following requirements shall be met:

a. All equipment, including spare circuit breakers, shall be installed in the switchboard section in accordance

with the shipboard configuration during testing.

b. All lengths of ship s cabling (except for spare and blank circuit breakers) and bus work shall be installed in

the switchboard section in accordance with the shipboard configuration during testing.

c. All lengths of ship s cabling (except for spare and blank circuit breakers) that extend outside the foundation

of the switchboard section shall be stubbed to 12- to 18-inch length with the bitter ends insulated.

d.

The test shall be conducted with all equipment and cables in the section energized with no load.

49

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business